EN124 C250 & D400 round SMC resin manhole cover

Sheet Molding Compound (SMC) is a compression molding compound often used for larger parts where higher mechanical strength is needed. SMC is a fiber reinforced thermoset material. As with BMC, thermoset Sheet Molding Compound (SMC) is a mixture of polymer resin, inert fillers, fiber reinforcement, catalysts, pigments and stabilizers, release agents, and thickeners and possesses strong dielectric properties.

Sheet Molding Compound (SMC) is a mineral filled, fiberglass reinforced polyester (vinyl ester and phenolic) based molding compound. SMC is a thermosetting material that undergoes an irreversible cross-linking reaction when exposed to the heat and pressure of the thermoset molding process (i.e. ambient delivery of material to a heated molding surface).A somewhat tacky, dough-like mass in its unmolded state, SMC is covered to an infusible, solid state using injection, compression and transfer methods.

SMC manhole cover

D400 manhole cover

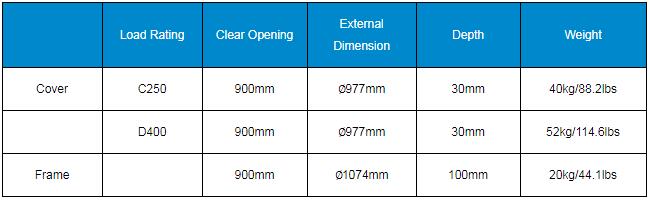

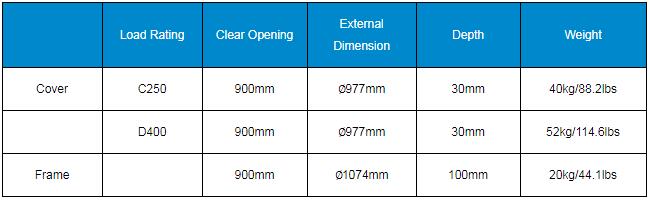

Materials for Clear Opening Ø900mm (Ø977mm) D400&C250 Cover & Frame

General classifications of manhole covers are below:

A-15 – 1,5 ton load resistance – Intended for surfaces, grating and other areas used by two-wheel vehicles and pedestrians

B-125 – 12,5 ton load resistance – Especially for surfaces or sidewalks comparable to parking grounds for tourist vehicles

C-250 – 25 ton load resistance – Intended for parking lots and sides of roads for heavy vehicles, side grooves, sidewalks and pedestrian zones on streets.

D-400 – 40 ton load resistance – For pedestrian streets, lanes, streets and roads (except side grooves)

E-600 – 60 ton load resistance – Also for special use in factories, dock areas and airports etc.

F-900 – 90 ton load resistance – Also for special use in factories, dock areas and airports etc.

The classification above comply with the standards EN 124 for Europe .

In addition, in need of both change of the metal / concrete and asphalt circle and raising manhole cover, the cover can be re-positioned with elevation apparatus.

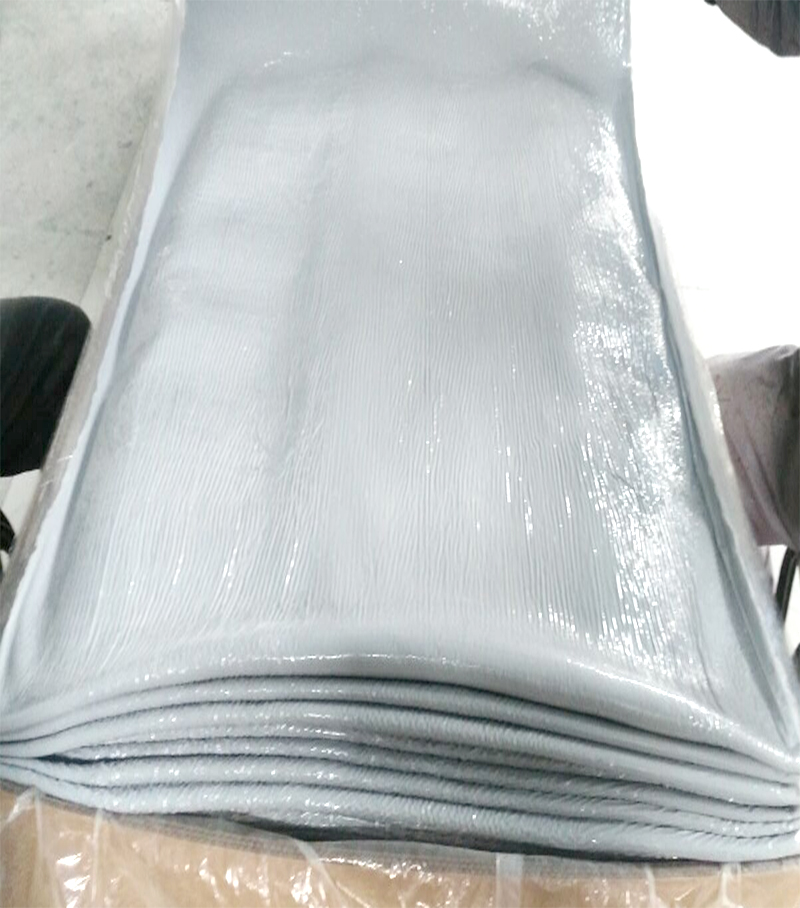

SMC Raw material

1.No recovery value and anti-theft—the plastic manhole covers use the SMC material and will solve the stolen problem thoroughly.

2.High load capacity—plastic manhole covers have a high load capacity exceeds the ductile iron strictly conforms to BS EN124 Standard.

3. Light weighted—manhole covers of composite material is 30% lighter than covers of iron, which allows easy transportation and maintenance.

4.Free-design—It can be designed according to users’ demands, including size,color, pattern, specification.

4.Long service life-it can be used at least 30 years.

5.Well sealed—-it can be used effectively prevent those poisonous gases leaking out from cesspool.

6.Logo application avaliable

FRP communication inspection manhole with cover | buried Communication cable inspection manhole

FRP communication inspection manhole with cover | buried Communication cable inspection manhole Plastic manhole with Composite cover for Rainwater collection and infiltration

Plastic manhole with Composite cover for Rainwater collection and infiltration High strength plastic drainage channel cover china | China HDPE Channel Trench Drain Cover

High strength plastic drainage channel cover china | China HDPE Channel Trench Drain Cover Plastic Oil-water separation chamber | grease interceptor|household kitchen oil and water filtration separation

Plastic Oil-water separation chamber | grease interceptor|household kitchen oil and water filtration separation Gmt composite manhole cover and gmt grating in China

Gmt composite manhole cover and gmt grating in China