SMC is short for sheet moulding compound. Thickness 1.5mm–3.5mm, width 500mm — 1200mm, coil supply or box-type tonnage package.When it is in use, the film can be removed by cutting and weighing and added into the heated mold. The product can be obtained by the time required to press and maintain the pressure

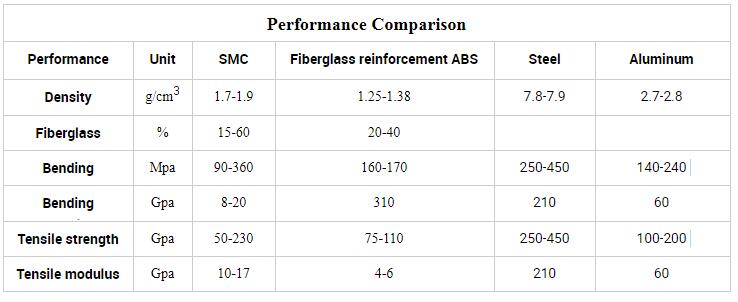

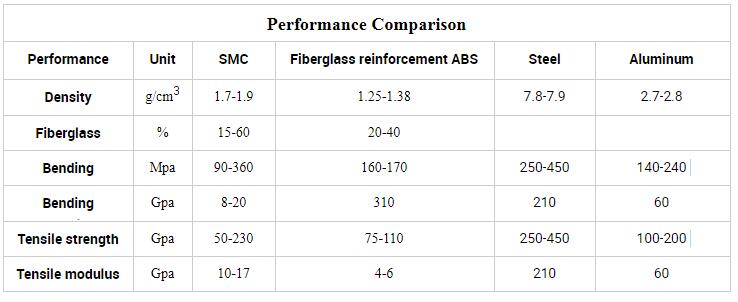

SMC (Sheet Moulding Compound) is a fibre reinforced compound, in a thermoset resin matrix, with mineral fillers and different additives. Generally thermoset unsaturated polyester resins are used as organic matrix. As reinforcement for SMC, both glass fibre or carbon fibre can be used.

With the aim of enhancing its characteristics and improve its transformation, other components are added: thermoplastic additives, pigments,demoulding agents, thickeners ,etc.

The storage temperature is recommended to be between 5ºC and 25ºC. Higher storage temperatures can significantly reduce the usability time of SMC.

SMC is mainly used in hot press compression moulding for the production of manhole cover,drainage grating,floor, bench slat,electric meter box,etc.

smc sheet Raw material

China SMC sheet

SMC -Sheet molding compound

The abbreviation of SMC is “sheet molding compound”.The main raw material are GF(special yarn),UP(unsaturated polyester resin),low shrinkage additives.MD(filler) and various of additives.it first appeared in Europe in the early 1960s and was developed in the United States and Japan in the around 1965. SMC has some unique solutions to the backwards of the wood ,steel,Plastic meter box,like easy aging,easy to corrode, poor insulation,cold resistance,poor flame retardancy,short service life,etc.The excellent properties of compound meter box are absolute seal waterproof performance,corrosion performance,preventing electricity-stolen performance,no need ground wire,appearance beautiful,having lock and complete sealing for security,long service life and so on. The Smc Cable bracket,cable trench bracket.smc meter box are widely used in the site,such as the reform of city network.

How to Produce SMC Raw material from Manufacturer in China ?

Produce SMC sheet from China

In order to have high quality products, the following storage conditions should be maintained:

(1) avoid high temperature, keep the temperature below 25 (2) avoid direct sunlight (3) do not damage the packaging during storage

Precautions in the workplace: (1) avoid direct sunlight and water. (2) the consumption of SMC sheets stored in the workplace shall not exceed one day. (3) once the aluminum film packaging is removed, the SMC sheet must be used in a short time. (4) SMC sheet should be exposed to air for not more than 5 mins after PE or PA film is removed. Otherwise, rewrap it with aluminum film.

SMC

Mold temperature under the hydraulic press :135-145℃

SMC is abbreviation of Sheet Molding Compounds, which mainly consists of the special spinning unsaturated resin, Low shrinkage agent, filler and many kinds of accessory ingredients.

Sheet Molding Compounds (SMC) is shaped by molding after high temperature, which characterize high mechanical strength, light material proportion, low cost, corrosion resistance, long working life, high insulation strength, anti-resistance, flame retardant and etc. the design of product is very flexible, and it iseasy to do scale production. The products characterize with safety and beauty which can be widely used in many fields such as electric, automobile industry, construction, communication, railway industry etc.

FRP communication inspection manhole with cover | buried Communication cable inspection manhole

FRP communication inspection manhole with cover | buried Communication cable inspection manhole Plastic manhole with Composite cover for Rainwater collection and infiltration

Plastic manhole with Composite cover for Rainwater collection and infiltration High strength plastic drainage channel cover china | China HDPE Channel Trench Drain Cover

High strength plastic drainage channel cover china | China HDPE Channel Trench Drain Cover Plastic Oil-water separation chamber | grease interceptor|household kitchen oil and water filtration separation

Plastic Oil-water separation chamber | grease interceptor|household kitchen oil and water filtration separation Gmt composite manhole cover and gmt grating in China

Gmt composite manhole cover and gmt grating in China