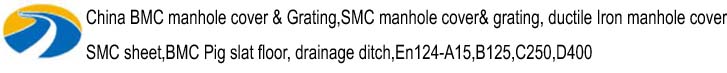

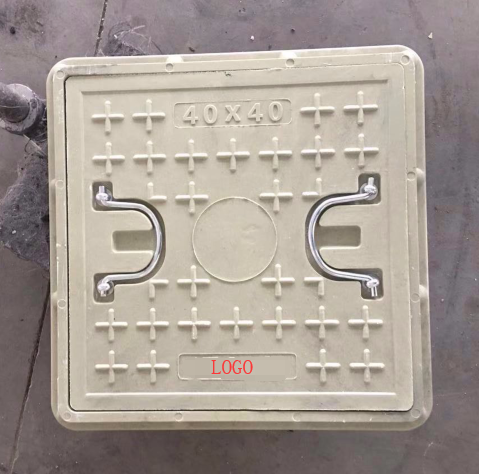

China BMC water grate or gully grate is made of BMC or SMC, we are a Manufacturer in Huzhou city, zhejiang,China. It is aslo called polymer drain cover,It is made of many kinds of chemical materials, such as steel bar and resin, which are pressed by high temperature.

Now we have many different sizes,like

750*450,380*740, 380*680 , 400*600, 400*500,500*500, 600*600,

350*500,300*500, 250*500 ,450*300, 350*250, 280*250,etc.

BMC gully gratings are the the abbreviation of bulk molding compounds gratings.People in China often called unsaturated polyester dough molding compound. The main raw material of GF (chopped glass fibers), UP (unsaturated polyester resin),MD (filler) and various additives made by mixing dough prepreg material.

It has the advantages of anti-corrosion, anti-theft, beautiful appearance, carrying capacity higher. It is suitable for the application of walk road, community, greening, park, swimming pool, front and back of the house drainage ditch and so on.

Our company produces and supplies various types of manhole covers, trench covers, composite manhole covers, polymer manhole covers, resin manhole covers, fiberglass manhole covers, polymer composite resin fiberglass manhole covers, water grates, inspection covers, anti-theft covers; well cover, ductile iron manhole cover, drain cover, Rain Water well cover, grass cover, tree guard board, gutter cover, electric well cover, gas well cover, open ditch cover, sewage well cover, composite cover, cable cover and other products are welcome to buy!

PRODUCT TRAITS

1. Light weight:

product weight is only about one third of cast iron, easy to transport, install, repair, greatly reducing the labor intensity.

2. High strength:

its strength is ten times as rigid PVC, much higher than the absolute strength of aluminum to achieve the level of ordinary steel;

3. Corrosion-resistant:

it stainless, no mold, no rot, no paint, the ability of many gas, corrosive liquid medium;

4. Fatigue resistance:

composite covers have some flexibility, which makes the people who work in the above long-term comfort, as a work platform, reducing the staff of the legs and back tension, increase the comfort of working to improve efficiency, human engineering scientists have been recommended;

5. The overall economic good:

with more than ordinary carbon steel, composite material covers integrated, low cost, although its one-time investment than ordinary carbon steel, because of its long life, and can be used two decades, and no maintenance, thus The overall economic efficiency is much better than using carbon steel

6. Easy installation:

the covers makes use of composite materials greatly reduce the weight of components, thus reducing the weight of the support structure, installation does not require use of lifting equipment, which saves and convenient.

7 Safety and security:

covers the installation and use of composite materials, the process will not crash and have a spark, especially for use in explosive environments, in addition, the covers with non-slip surface to prevent sliding down to reduce accidents.

Customer logo marking available

FRP communication inspection manhole with cover | buried Communication cable inspection manhole

FRP communication inspection manhole with cover | buried Communication cable inspection manhole Plastic manhole with Composite cover for Rainwater collection and infiltration

Plastic manhole with Composite cover for Rainwater collection and infiltration High strength plastic drainage channel cover china | China HDPE Channel Trench Drain Cover

High strength plastic drainage channel cover china | China HDPE Channel Trench Drain Cover Plastic Oil-water separation chamber | grease interceptor|household kitchen oil and water filtration separation

Plastic Oil-water separation chamber | grease interceptor|household kitchen oil and water filtration separation Gmt composite manhole cover and gmt grating in China

Gmt composite manhole cover and gmt grating in China